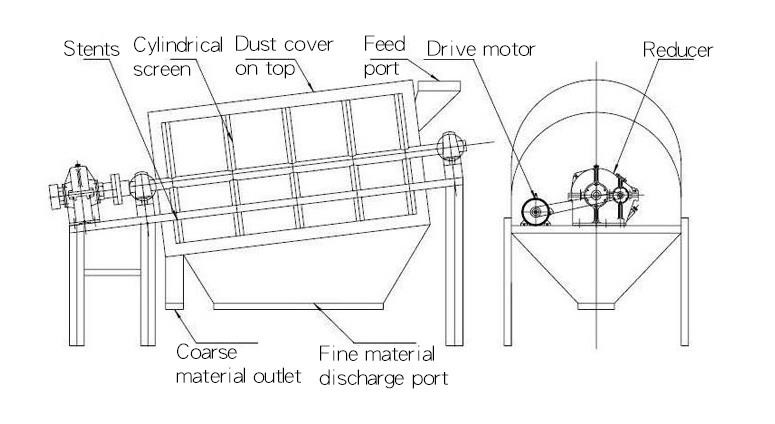

rotary drum screen

Usage and application:

The rotary drum screen machine is a new type of self-cleaning material-screening special equipment. It is widely used in screening various solid materials that size less than 300mm.

Working principle:

The raw materil fed Into the large-capacity storage hopper, the raw material is put into the flat sieve cylinder through the feeding belt, and the rotating sieve cylinder drives the raw material to form the artificial sieve effect of the raw material sliding on the screen surface.

Under the pushing and tumbling of the inner blade of the cylinder, the finished sand falls on the finished sand belt through the collecting hopper, and is lifted down by the belt into a finished material pile or directly into the storage hopper.

The whole process is continuous and the material classification is clear and accurate.

Feature:

1.Mesh is not easy to block, automatic cleaning brush on the top of trommel screen to avoid the blockage.

2.Smooth operation, low noise.

3.High screening efficiency, Large screening capacity

4.Simple structure, easy maintenance.

5.Sieve drum can be closed, easy to close the dust collection.

6. Convenient maintenance, the upper hood is removable.

Technical specifications:

|

Model |

Capacity |

Power |

Screen Diameter |

Screen Length |

Discharge Size |

Input Size |

Dimension |

Weight |

|

(t/h) |

(kw) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

(kg) |

|

|

GTS1015 |

50 |

3.0 |

1000 |

1500 |

0~100 |

≤300 |

2600×1400×1700 |

2200 |

|

GTS1020 |

100 |

4.0 |

1000 |

2000 |

3390×1400×2140 |

2800 |

||

|

GTS1225 |

160 |

5.5 |

1200 |

2500 |

4146×1600×2680 |

4200 |

||

|

GTS1530 |

250 |

7.5 |

1500 |

3000 |

4460×1900×2820 |

5100 |

||

|

GTS1545 |

350 |

11 |

1500 |

4500 |

≤400 |

5960×1900×3080 |

6000 |

|

|

GTS1848 |

450 |

15 |

1800 |

4800 |

6500×2350×4000 |

7500 |

||

|

GTS2055 |

600 |

22 |

2000 |

5500 |

7500×2550×4800 |

9600 |

||

|

GTS2265 |

800 |

30 |

2200 |

6500 |

8500×2750×5000 |

12800 |

Get a Quote