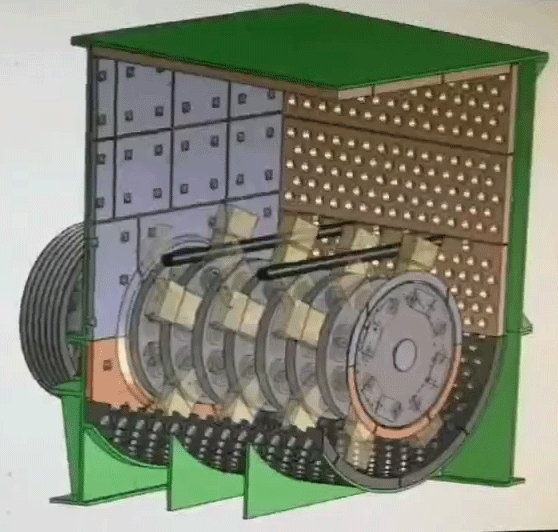

Box stone crusher

Usage and application:

Box crusher is also mainly applied to the compressive strength in the upper and lower hardness of the following materials, one or two broken. Especially for mining, building materials, chemicals, metallurgical industry with the broken materials

Working principle:

The stone falls straight from the top of the machine into the high-speed rotating turntable. Under the action of high-speed centrifugal force, high-speed impact and high-density crushing are produced. After the stones hit each other, they will form a vortex motion between the turntable and the casing. Repeatedly hitting, rubbing, and crushing each other until it is crushed to the required particle size. The box-type crusher has a large single hammer head, high rotor speed, and large hammer head moment of inertia, which realizes the cannibalistic crushing of super large stones.

Features:

1) Simple and reasonable structure , easy in installation and maintation.

2) Low running cost.

3) High-performance, safe and reliable drive solution.

4) Big crushing ratio.

Technical specifications:

|

|

800×800 |

1000× 1000 |

1200×1200 |

1400×1400 |

1600×1600 |

1800×1800 |

|

Roller diameter(mm) |

800 |

1000 |

1200 |

1400 |

1600 |

1800 |

|

Roller length(mm) |

800 |

1000 |

1200 |

1400 |

1600 |

1800 |

|

Capacity(t/h) |

70-100 |

90-120 |

130-160 |

190-210 |

250-300 |

300-400 |

|

Feeding size(mm) |

≤600 |

≤800 |

≤900 |

1000 |

≤1000 |

≤1200 |

|

For stone |

Pressure 300MPa various types of stone |

|

||||

|

Power(kw) |

55-75 |

55-75 |

75-90 |

132-150 |

160-210 |

280-320 |

Get a Quote