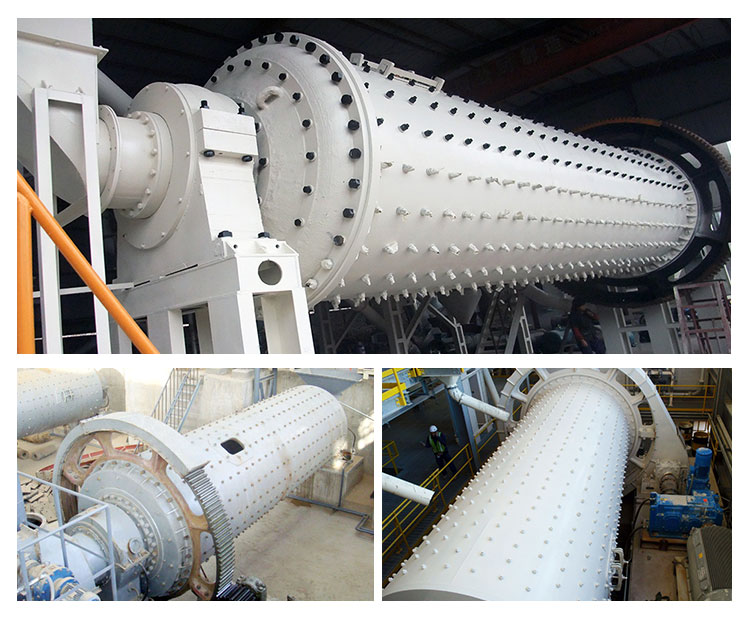

ceramic ball mill

Usage and application:

Ceramic ball mill is ball mill with ceramic liner,and the grinding balls are ceramic balls ,it is used for grinding feldspar,quartz,clay,ore without iron polluction for ceramic industry .

Working principle:

The ball mill is a homitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ceramic liner and different specifications of ceramic balls in the chamber. The centrifugal force caused by rotation of barrel brings the ceramic balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Features:

1. The main bearing of the ball mill adopts a large-diameter double-row self-aligning stick bearing instead of the original sliding bearing, which reduces friction and energy consumption, and the mill is easy to start.

2. The end cap structure of ordinary mills is retained, with large diameter inlet and outlet openings and large processing capacity.

3. The feeder is divided into two types: combined feeder and drum feeder, with simple structure and separate installation.

4.There is no inertial impact, the equipment runs smoothly, and the maintenance time of the mill is reduced and the efficiency is improved.

Technical specifications:

Technical specifications:

|

Models |

Drum speed |

Ball load |

Feed size |

Discharging size |

Yield |

Motor power |

Total weight |

|

|

Ф900×1800 |

36-38 |

1.5 |

≤20 |

0.075-0.89 |

0.65-2 |

18.5 |

5.85 |

|

|

Ф900×3000 |

36 |

2.7 |

≤20 |

0.075-0.89 |

1.1-3.5 |

22 |

6.98 |

|

|

Ф1200×2400 |

36 |

3 |

≤25 |

0.075-0.6 |

1.5-4.8 |

30 |

13.6 |

|

|

Ф1200×3000 |

36 |

3.5 |

≤25 |

0.074-0.4 |

1.6-5 |

37 |

14.3 |

|

|

Ф1200×4500 |

32.4 |

5 |

≤25 |

0.074-0.4 |

1.6-5.8 |

55 |

15.6 |

|

|

Ф1500×3000 |

29.7 |

7.5 |

≤25 |

0.074-0.4 |

2-5 |

75 |

19.5 |

|

|

Ф1500×4500 |

27 |

11 |

≤25 |

0.074-0.4 |

3-6 |

110 |

22 |

|

|

Ф1500×5700 |

28 |

12 |

≤25 |

0.074-0.4 |

3.5-6 |

130 |

25.8 |

|

|

Ф1830×3000 |

25.4 |

11 |

≤25 |

0.074-0.4 |

4-10 |

130 |

34.5 |

|

|

Ф1830×4500 |

25.4 |

15 |

≤25 |

0.074-0.4 |

4.5-12 |

155 |

38 |

|

|

Ф1830×6400 |

24.1 |

21 |

≤25 |

0.074-0.4 |

6.5-15 |

210 |

43 |

|

|

Ф1830×7000 |

24.1 |

23 |

≤25 |

0.074-0.4 |

7.5-17 |

245 |

43.8 |

|

|

Ф2100×3000 |

23.7 |

15 |

≤25 |

0.074-0.4 |

6.5-36 |

155 |

45 |

|

|

Ф2100×4500 |

23.7 |

24 |

<25 |

0.074-0.4 |

8-43 |

245 |

56 |

|

|

Ф2100×7000 |

23.7 |

26 |

<25 |

0.074-0.4 |

12-48 |

280 |

59.5 |

|

|

Ф2200×4500 |

21.5 |

27 |

<25 |

0.074-0.4 |

9-45 |

280 |

54.5 |

|

|

Ф2200×6500 |

21.7 |

35 |

<25 |

0.074-0.4 |

14-26 |

380 |

61 |

|

|

Ф2200×7000 |

21.7 |

35 |

<25 |

0.074-0.4 |

15-28 |

380 |

62.5 |

|

|

Ф2200×7500 |

21.7 |

35 |

<25 |

0.074-0.4 |

15-30 |

380 |

64.8 |

|

|

Ф2400×3000 |

21 |

23 |

<25 |

0.074-0.4 |

7-50 |

245 |

58 |

|

|

Ф2400×4500 |

21 |

30 |

<25 |

0.074-0.4 |

8.5-60 |

320 |

72 |

|

|

Ф2700×4000 |

20.7 |

40 |

<25 |

0.074-0.4 |

22-80 |

380 |

95 |

|

|

Ф2700×4500 |

20.7 |

48 |

<25 |

0.074-0.4 |

26-90 |

480 |

102 |

|

|

Ф3200×4500 |

18 |

65 |

<25 |

0.074-0.4 |

According to the process conditions |

630 |

149 |

|

|

Ф3600×4500 |

17 |

90 |

<25 |

0.074-0.4 |

According to the process conditions |

850 |

169 |

|

|

Ф3600×6000 |

17 |

110 |

<25 |

0.074-0.4 |

According to the process conditions |

1250 |

198 |

|

Get a Quote