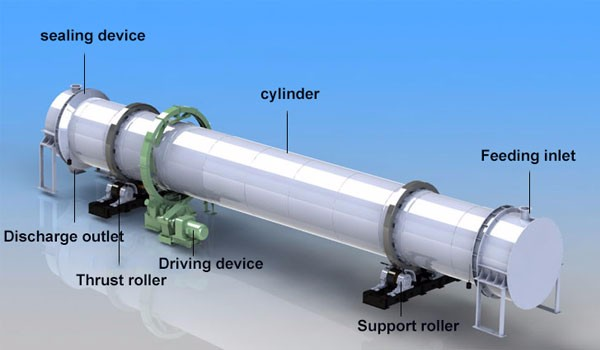

rotary cooler

Usage and application:

Rotary Cooler is one of the main equipments in rotary kiln production system.

Its role is to cool the 1000~1300°C clinker from rotary kiln to 200°C and below by heating exchange of moving materials and airflow inside the rotating barrel.

The quality and grindability after cooling down is improved. The air from cooling clinker is injected into kiln, as secondary circulating air, raising the thermal efficiency of kiln.

Working principle:

In the natural situation, the slope of Cooler cylinder is 3.5% to 5%, keeping low-speed rotation. The material is feeding from end of Cylinder (high side), circular lifting plate keeping the materials scatter lifting and moving down. Cooling material is discharged from the low end, and preheated air is sending into the rotary kiln for calcinations.

Technical specifications:

|

Specification |

Capacity |

Installation obliquity (%) |

Main reducer |

Main motor (KW) |

|

Φ1.5×15 |

2~3 |

3~5 |

ZQ500 |

15 |

|

Φ1.5×20 |

3~4 |

3~5 |

ZQ500 |

15 |

|

Φ1.8×18 |

4~6 |

3~5 |

ZQ500 |

18.5 |

|

Φ2.0×22 |

7~8.5 |

3~5 |

ZQ500 |

22 |

|

Φ2.2×18 |

7~8.5 |

3~5 |

ZQ500 |

22 |

|

Φ2.2×22 |

8~10 |

3~5 |

ZQ650 |

30 |

|

Φ2.5×25 |

15~20 |

3~5 |

ZS125 |

55 |

|

Φ2.8×28 |

16~22 |

3~5 |

ZL100 |

55 |

|

Φ3.0×30 |

20~25 |

3~5 |

ZL115 |

75 |

|

Φ3.2×36 |

28~32 |

3~5 |

ZL115 |

90 |

|

Φ3.3×40 |

32~36 |

3~5 |

ZL130 |

132 |

Get a Quote